|

|

|

| |

|

|

Sand shading (or

scorching),

as it’s name implies, is the art of applying

heat to veneer in order to achieve shadow and

depth in circumstances where it would not be

possible to attain the required effect by

inserting a piece of darker veneer into the

work.

Sand shading-scorching can be used to give a

smooth gradual darkening which is often

impossible to achieve just by “cutting in”

another piece of veneer.

To

demonstrate the overall effect, take a look at

these examples of sand scorching (as we shall

now refer to it) shown on this accompanying

picture.

The

Roses seen here owe a lot of their realism to

sand scorching, for example, the depth and

roundness shown in the petals, this couldn’t

really be achieved with any other method. It can

also be used successfully for shadows fading

into corners, or even for scallops and sea

shells such as you can see in this other

picture.

|

|

|

To

acquaint yourself with sand scorching I would

advise you to try experimenting with various

veneers to see what kind of effect’s you can

achieve.

Naturally the best veneers for sand scorching

are the whiter veneers, such as sycamore, ash,

or holly, any of these veneers would scorch

well, but if you wish, you can make use of other

veneers.

Mind you

I have never had much success with the dyed

variety of veneers, they never scorch with as

much satisfaction as the whiter veneers do.

Now, we

need at this juncture, to make some observations

about the actual sand you could use.

You can

use either coarse or fine sand, I have never

found any real difference between the grades of

sand myself, although some people do say that

they think that coarse sand is the better, but

the final choice is up to your own personal

preferences.

|

|

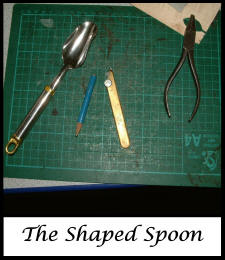

You will

want a pan to hold your sand, of which you will

want a depth of about an inch to an inch and a

half of the sand (approximately 2 – 3.5cms), you

will also need a pair of pliers or tweezers and

an electric stove (as an alternative you could

make use of a gas stove or a “camping” or picnic

type of heater). It will take a little while for

your sand to heat up this will be roughly about

20 minutes or so. You will also be needing a

spoon (a dessert spoon is ideal for this) but

make sure it is not from your best cutlery

otherwise you’ll invite a fair bit of domestic

disharmony into the proceedings, because you

will now need to place the spoon in a vice and

squeeze the sides in so that the spoon forms a

pouring spout (as you can see in this photo).

This deformation will give you better control

with the pouring of the hot sand.

I wouldn’t advise you to

dip your veneer straight into the hot sand

because you will burn it and you will have lost

the desired effect, you will in fact have over

burnt it. There are certain exceptions to this

statement but I will be showing you them later

on when I do the trellis and the basket weave

demonstrations.

|

|

|

Unfortunately with very small pieces you won’t

be able to hold them and pour sand onto them,

you will of necessity be obliged to dip them in

the hot sand, but do be very careful and don’t

burn them by leaving them in the hot sand for

too long.

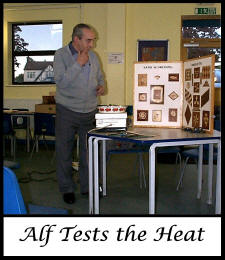

It’s

time now for some practical work, I’ll just

check the sand for heat by just letting some hot

sand rest on the test piece of veneer for a few

seconds, yes, that’s okay it’s scorching so I

will turn the heat down a little.

You will

notice that scorching has been taking place at

the sides of the test veneer, so we are now at

our correct heat.

Now when

you cut your piece of veneer for scorching you

can either cut your piece slightly oversize, or

you can cut it to fit the “window”, the choice

is yours.

Do bear

in mind that the hot sand applied to the veneer

will cause the veneer to shrink a little due to

the effect of the heat causing some of the

moisture in the wood to evaporate,

|

|

so it

will be necessary to put some moisture back into

the veneer to bring it back to it’s original

size, this you can do by just putting the

scorched veneer into your mouth, obviously, make

sure its cooled slightly otherwise you’ll burn

yourself.

If you

elect to cut your piece of veneer oversize then

it will only be necessary to trim your veneer to

fit your window and then you will avoid having

the taste of scorched veneer in your mouth. I

would recommend that you lightly pencil the area

you want to scorch for your own guidance when

applying the hot sand. Don’t forget to apply the

sand to both sides of your veneer so that you

get penetration of the “scorch”.

When you

apply the hot sand to the veneer, scorch

slightly over the area you require, because you

will lose some of the scorched effect when you

come to sand your picture down. You cannot

really get the scorching effect with dark woods,

for example, a walnut, you can try sand

scorching if you wish but you are not going to

make hardly any impression on it at all. If you

use a light walnut, it could perhaps be used to

depict a corner of a room or ceiling.

Now, if

you have a fair number of pieces to scorch, just

scorch a few of these first and put them back

into your picture, then do another few and put

them in your picture, and carry on with this

procedure until you have done all the pieces you

wanted scorched for your picture.

|

|

|

A question from the audience: “You don’t

moisten the veneer until after you’ve scorched

it Alf?” “Yes, that’s right, now if you assume

that the piece of veneer you’ve just scorched is

going back into your picture, you’ll probably

find that there is now a gap around it even

though it fitted perfectly before you scorched

it, this will be due to shrinkage caused by

moisture loss because of the effect of the hot

sand, now you can overcome this problem by

applying a little moisture, even the white PVA

glue will help the situation. If you are not

happy with this shrinkage problem you can

overcome these drawbacks by just cutting your

veneer oversize, sand scorching it and then

cutting it into your window in the normal

manner”.

Do not try placing hot sand into the middle

of a leaf of veneer because it will start

curling up and you will be unable to do anything

of any practical use with it.

I must say that I’ve not had any real success

with chemically treated veneers either. You can

sometimes see a light scorching taking place,

but it in no way compares with the depth of the

effect you get when you scorch the white

veneers.

|

|

Now do bear in mind that the sand in the

centre of the tin is going to be the hottest, so

don’t go plunging your veneer into that part of

the hot sand and then after a while bring it out

from that part of the sand only to find that you

now have a charred piece of veneer, it is far

better to control the application of the hot

sand by pouring it on your veneer with the

spoon. As I said before, with small pieces you

will not be able to do that, but with your

larger pieces do use the spoon to apply the sand

onto your veneer, leave it for a few seconds

then pour the sand back into the tin. You can

repeat this process until you’ve achieved the

depth of scorching that you require.

If you take a look at the roses on the

demonstration board you will find that they’ve

scorched just right, they show about the right

amount of shadow and depth, after all, you do

not want the wood blackened by over doing the

amount of scorching.

|

|

|

Alf: “anyone like to have a try?”

Vicky volunteers.

Alf:

“I’ll just check that the heat’s okay for you”

Vicky now applies some hot sand to a piece of

test veneer by using the spoon method.

Alf:

“there you are, you can see the discolouration

taking place, now turn it over and do the other

side, ------ there, that’s now a sufficient

depth of colouring”

Dave Walker:

“don’t forget to place the veneer in your mouth

to resize it!”

|

|

A question from the audience: “Can I dip the

piece of veneer into water instead of placing it

in my mouth?” “Yes, but do not let it soak, test

it out on a spare piece of scrap veneer first,

or use the other alternative of cutting your

veneer oversize”

Another question from the audience: “Can you

use coloured dyed veneers?” “I have, as I said

previously, never had any success with dyed

veneers, but do try experimenting with these

types of wood because you may be successful”

There is one wood I would not recommend you

to use, and that is Paduak, this is a red wood

and it bleeds its colour very easily, when it is

scorched it just crumbles and you just end up

wasting your time and your materials. As I said

earlier, the best results are obtained with the

use of the white woods, sycamore, holly, horse

chestnut and ash to name just a few. But do

experiment because it is all a case of trial and

error. It is well worth the effort and the time

you put into getting yourself the desired

effect.

|

|

|

A further question from the audience:

“What sort of sand do you use Alf?” “I use any

sort of soft or sharp sand. I think this is

actually sharp sand that I am using for this

demonstration. Many people say that they find

sharp sand is the best”

Another question from the audience:

“A lot of the secret of it Alf must be the

amount of heat you put into the sand?” “It takes

roughly about 20 minutes to heat the sand, you

can easily get the sand too hot, so do a test

with a scrap piece of veneer before you commit

any of your picture veneers to the hot sand, one

last point though is don’t leave the spoon in

the hot sand while you are scorching otherwise

you’ll end up not only scorching your veneer,

but you will burn your little marquetarian’s

fingers into the bargain when you go to pick up

the spoon again!”

|

|

An

over heard remark from Harry Heyford to

Derek Batts: “I do the sand scorching in

my shed, I bought a little Calor gas

burner and I use it down there” “What,

did you set the shed on fire?” “Well,

yes, but……..”

|

|

Final applause from

the audience.

End of the Lecture.

Alf's next lectures

in this series will cover the topics of

Trellis and Basket weave

|

|

Next

Lecture >

|

|